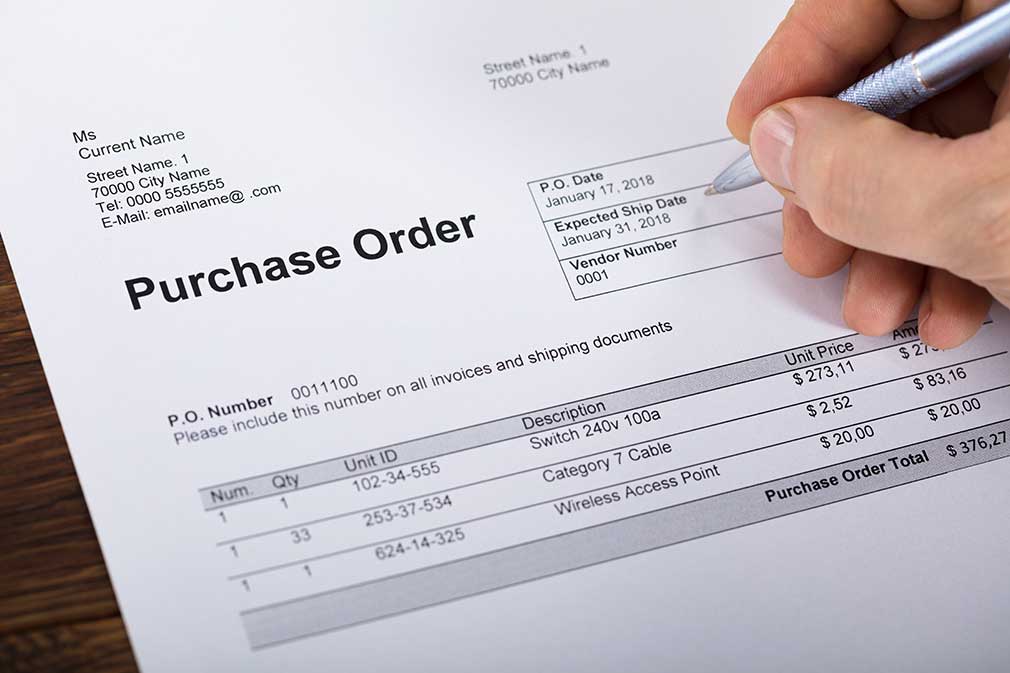

This topic is centred on the creation of purchase orders, purchase orders can be created from the Purchase Control menu option. In this topic you will learn how to create the commercial document and first official offer issued by a purchaser to a supplier, indicating types, quantities, and prices for products or services. The process will deal with creating stock orders to an external source from your branch.

This topic will run through Inter-Branch Orders (IBO’s) in the Purchase Control menu. An IBO is created when one branch wants to replenish its own stock by ‘pulling’ stock from another branch that has free stock available. Branches can order from each other when one branch is holding available stock that the other branch requires.

The process is similar to an Inter-Branch Transaction (IBT), although there is no end customer for onward delivery of the goods.

The sessions in this topic are for users receiving goods into a branch. When goods arrive from a supplier, you must receipt them against an existing purchase order that has been raised on the system. In addition to receiving goods in, this topic will run through the process of dealing with shortages and over-supply.

When lines from SOP are put on Back to Back (line status PUR) they are placed in Requisitions by the system at the time when the Sales order is processed. They remain there until they are allocated to purchase orders and then processed. The Action requisitions option is where you carry out this procedure of allocation and processing. You can allocate lines to existing purchase orders, or create new orders.

The toolbar and menu bar on the Action Requisitions form offer a number of options specific to this area of Purchase Control.

This topic looks at goods receiving orders that are linked to a sale on the system. Non-stock and special orders will be received from Purchase Control, whilst automatically updating through to the sales order.

This topic will run through the process of receiving direct orders in Purchase Control. There are many types of direct orders within K8, all dealing with scenarios whereby goods are not received into your own premises at any time of the lifespan of the order. In this course we you will see the process of receiving goods on behalf of the Customer.

Receiving Inter-Branch Transactions (IBT’s) will be addressed in this topic. An IBT needs to be received into stock in order for goods to be picked and delivered to the customer; you will see how receiving the goods will automatically update the sales order.

This topic deals with returning goods to a supplier from within Purchase Control. You will look at returning goods to a supplier in exchange for a credit. These goods are currently held on your system, either in your stock location or in a specific ‘damaged stock’ location.

There are two different processes for returning goods:

- Convert to Return

This is used when returning goods from an original purchase order created and received into your system.

- Returns to Supplier

This is used when returning goods that are not linked to the original purchase order. This may have to be used if the original purchase order was created on a legacy system.